- 👨🔧 Premium After-sale service

- 🚚 Free delivery from €39.90

- 📦 Return under 14 days

- ✉️ Customer service

Ultrafuse 17-4 PH BASF - 1.75mm - 3 kg

The Ultrafuse® 17-4 PH metal filament from BASF is a martensitic stainless steel. It performs better thanUltrafuse 316L during the debinding and sintering phase.

VAT at 20%, which is €418.80 TTC including tax.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 2000 products

A wide choice of products from the biggest brands

Use of the filament Ultrafuse 17-4 PH BASF

The Ultrafuse 17-4 PH filament is a very specific metal 3D printing filament developed by the Forward AM branch of the manufacturer BASF. It is not a filament whose purpose is to offer a metal appearance but rather a material enabling the manufacture of 100% metal objects in stainless steel(Type 630) from 3D filament in 2 steps.

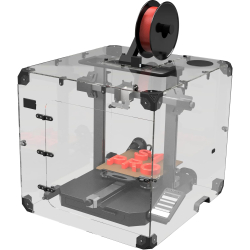

This Ultrafuse 17-4 PH filament is quite revolutionary, making it possible to produce parts for sintering using a conventional FDM 3D printer. Sintering is a high-temperature heating process (>1000°C) that separates the plastic from the metal. Once the plastic has been released, the metal enters the fusion phase, enabling the final restructuring of the 100% metal object.

It is at this point that dimensional shrinkage (which must be anticipated) occurs.

This 2-stage printing process starts with you printing the green part or the part to be sintered, then an external service provider performs the final sintering stage. This unique filament combined with a dedicated service provider is the recipe for minimising the production costs of your metal parts.

With this filament BASF 17-4 PH, gain access to metal printing technology by layer deposition without having to make a major investment.

With very high mechanical resistance to temperatures of up to 315°C and to corrosion, parts 3D printed with 17-4 PH are ideal for the automotive, petrochemical, aerospace and medical sectors.

Ultrafuse 17-4 PH BASF: key strengths

Accessible metal printing: This 17-4 PH filament (named after the stainless steel of which it is made) has been developed by BASF and is the first filament to enable reliable printing of a metal part for sintering. Available for most 3D printers FDM, this 2-step manufacturing process is fast, efficient and affordable.

Better printability and higher hardness: The design of this high-composite filament is based around a plastic matrix that enables good thread sliding, efficient extrusion and good interlayer bonding despite the high metal content. This 17-4 PH version has lower deformation and better mechanical strength.

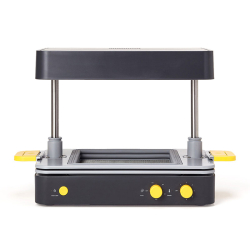

Optimised sintering method: The use of Ultrafuse 17-4 PH filament makes a specific sintering solution available. By using dedicated coupons (1 coupon = 1 kilo of part to be sintered), it's quick and easy to benefit from this complete solution.

If you'd like to find out more about the subject, we invite you to consult the guides available to download and discover the coupon system in the dedicated sheet.

Our recommendations for use with BASF Ultrafuse 17-4 PH

The Ultrafuse 17-4 PH filament requires appropriate settings. We recommend using the existing print profiles in order to respect the constraints specific to this filament. Printing must be precise and consistent, with a fill density, shell thicknesses, flux and other parameters to be used. These are extremely important for the second processing phase.

Specific media management is required, and the use of double extrusion will help in this second stage. The 17-4 PH is compatible with most FDM or FFF printers but is really recommended for professional printers. Be careful not to exceed the recommended extrusion temperature, otherwise the product will be highly toxic.

The use of a specific adhesive solution (Magigoo Metal) is also recommended to prevent your parts coming unstuck during printing. A hardened steel nozzle is also highly recommended due to the highly abrasive nature of this 3D wire.

We invite you to consult the attached documents for the essential data and information on printing with this very special filament. We will of course be on hand to guide you through the process.

- 🎯 We collaborate with businesses.

- 📦 Stock in Europe

- 🚚 Ships within 24 hours

- 🔐 Secure payments

- 🔙 14 days to change your mind

- 📱 Need advices ? Contact technical support

Specifications for Ultrafuse 17-4 PH BASF - 1.75mm - 3 kg

Technologie / Produit

- Technology

- FDM

- Material

- Other

- Visual aspect

- Opaque

- Diameter

- 1.75 mm

- Sensitivity to humidity

- Strong

- Odour

- Yes

- Harmful

- Yes

- Level of difficulty

- Expert

- Brand

- BASF

- Type of product

- 3D Filament

- Colour

- Natural

- Net weight

- 3 kg

Valeurs techniques

- Specific properties

- Metal to be sintered

- Resistors

- Mechanical engineering

Extrusion

- Nozzle type

- Tempered steel, Ruby

- Type of consumable

- Non-proprietary filament (open system)

- Min. plateau temperature

- 90 °C

- Max. tray temperature

- 120 °C

- Min. extrusion temperature

- 230 °C

- Max. extrusion temperature

- 250 °C

- Min. speed

- 15 mm/s

- Max. speed

- 50 mm/s

- Minimum nozzle diameter

- 0.5 mm

- Bowden compatibility

- Yes

- Warping sensitivity

- Strong

- AMS compatible

- No

Équipements spécifiques

- Closed printing enclosure

- Yes

- Filtration

- HEPA, Coal

Installation / Prérequis

- Type

- Filament on spool

- Box supplied

- Yes

- Coil material

- Plastic

- Also find this product Ultrafuse 17-4 PH BASF - 1.75mm - 3 kg in these categories:

- 3D Filament

- Composite filaments

- XL format

- Metal filament

- BASF

- 1.75 mm

Customer reviews about Ultrafuse 17-4 PH BASF - 1.75mm - 3 kg

You might also like