The Ultrafuse 316L from BASF filament is a revolutionary filament that allows you to produce stainless steel parts!

VAT at 20%, which is €464.40 TTC including tax.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 2000 products

A wide choice of products from the biggest brands

The Ultrafuse 316L filament from the manufacturer BASF is a very specific 3D printing filament. It is not just a filament designed to give a metallic appearance, but a filament that allows the production of 100% metal objects in 2 steps.

This filament Ultrafuse 316L is a revolutionary filament, enabling the production of sinterable parts through traditional FDM 3D printing. Sintering is a high-temperature process that separates the plastic structure from the metal. This sintering process melts the metal, creating an efficient and homogeneous bond.

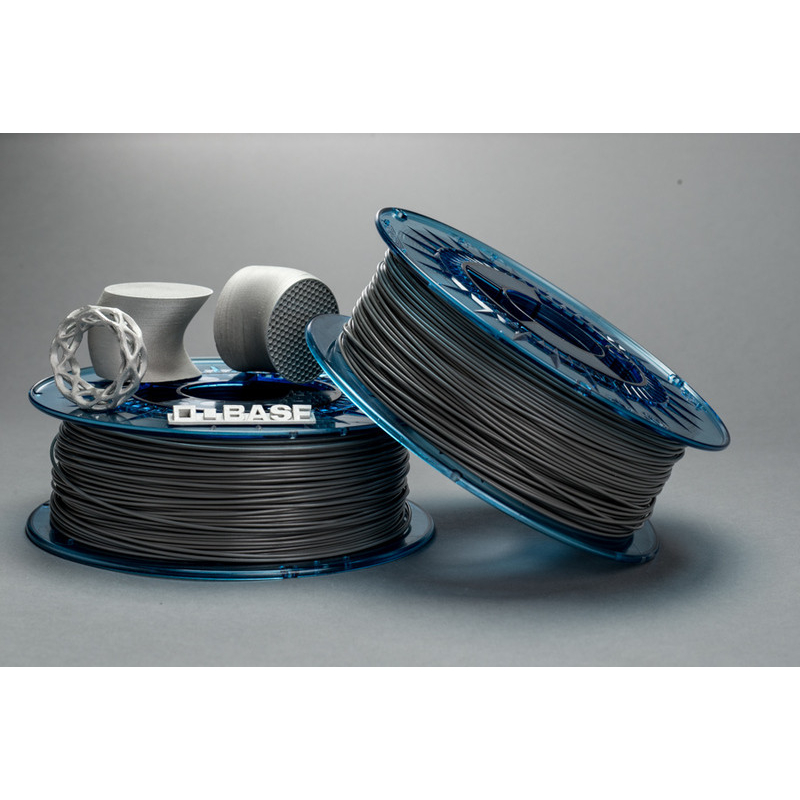

This 2-step printing process begins at home with the printing of the sinterable part (called "green") followed by the intervention of a provider for the sintering step. This combination of an ultra-technical filament and an external dedicated provider minimizes the cost of manufacturing metal parts without requiring a significant investment.

Affordable metal printing: This 316L filament (named after the stainless steel it is composed of), developed by BASF, is the first filament that allows the printing of a sinterable metal part. Accessible to most 3D printers on the market, this 2-step printing process is fast, efficient, and cost-effective.

Good printability: The design of this highly composite filament is developed around a plastic matrix that allows good filament flow, efficient extrusion, and strong inter-layer bonding despite the high metal content.

Optimal sintering method: This Ultrafuse 316L filament provides easy access to a sintering solution specific to this filament. By acquiring a dedicated coupon (1 coupon = 1 kilogram of part to sinter), it is simple and quick to access this post-processing solution.

If you need more information on the subject, we invite you to consult the available downloadable guides and the operation system of the coupon in the dedicated page.

The Ultrafuse 316L filament requires specific settings. It is highly recommended to use existing print profiles in order to meet the filament's constraints. Printing must be precise and uniform, including infill density, shell thicknesses, and flow rates. These parameters are extremely important for the second treatment phase.

A very specific support management is also necessary, and using dual extrusion will greatly help in this part. This filament is compatible with most FDM printers but is strongly recommended on professional printers.

Be careful not to exceed the recommended extrusion temperature to avoid high toxicity.

The use of a specific adhesive such as Magigoo Metal is also recommended to minimize warping of your parts during printing.

We invite you to consult the attached documents to obtain the essential data and information for printing this unique filament.

We will, of course, be available to assist and guide you in using this filament.

Specifications for Ultrafuse 316L Steel BASF - 1.75mm - 3 kg

Technologie / Produit

Extrusion

You might also like