- 👨🔧 Premium After-sale service

- 🚚 Free delivery from €39.90

- 📦 Return under 14 days

- ✉️ Customer service

Resins for 3D printers

Discover our selection of resins for LCD and SLA printers, featuring top brands like Elegoo, Anycubic, Creality..., available in stock with fast delivery.

Find the right resin for your needs: standard, dental, flexible, high-speed, or tough, in 500 ml and 1000 ml formats. Choose high-quality materials compatible with most 3D printers.

Showing 101-130 of 130 item(s)

Active filters

- -€10.00 excl. VAT

- -€50.00 excl. VAT

- -30%

- -20%

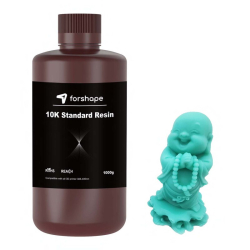

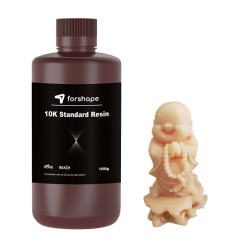

10K Ortho Model Water Washable resin Forshape Premium - 1 kg

€32.90 excl. VAT

€26.32 excl. VAT

Out of stock

- -20%

- -€7.42 excl. VAT

- -€7.42 excl. VAT

- -€7.42 excl. VAT