- 👨🔧 Premium After-sale service

- 🚚 Free delivery from €39.90

- 📦 Return under 14 days

- ✉️ Customer service

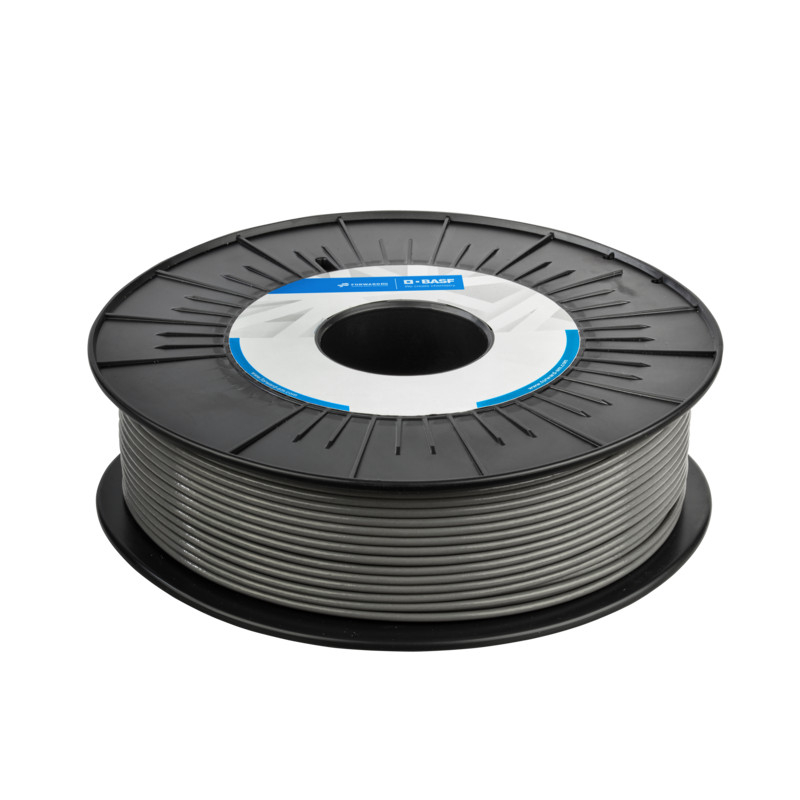

Ultrafuse 316L Metal BASF - 2.85mm - 3 kg

VAT at 20%, which is €464.40 TTC including tax.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 2000 products

A wide choice of products from the biggest brands

Utilisation du filament Ultrafuse 316L BASF

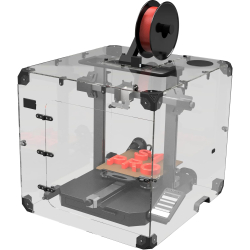

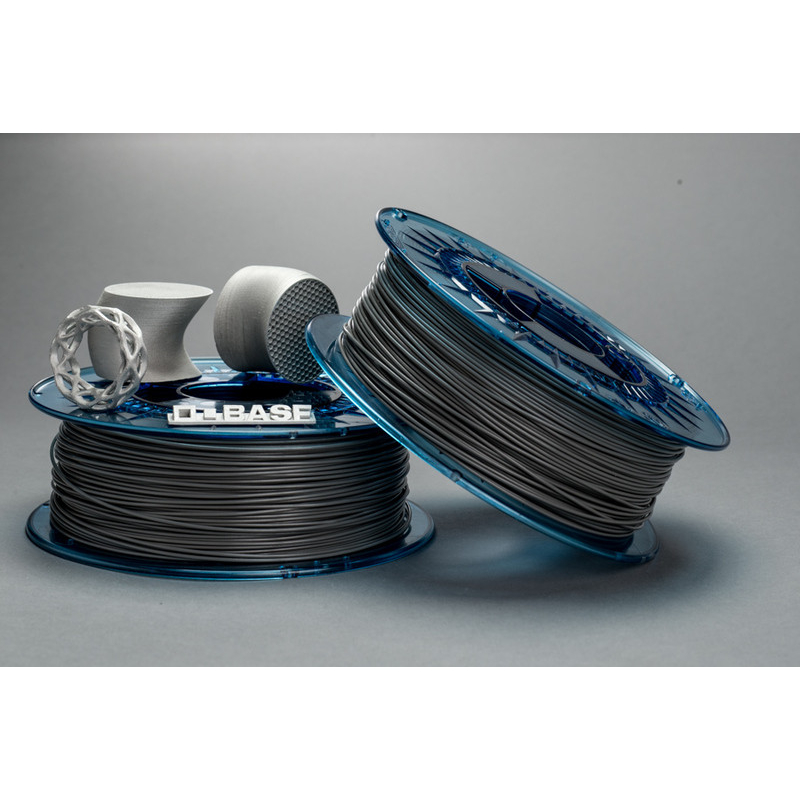

Le filament Ultrafuse 316L du fabricant BASF est un filament d’impression 3D bien spécifique. Ce n’est pas un simple filament qui a pour but de révéler un aspect métallique mais bien un filament permettant en 2 étapes la fabrication d’objet 100% métallique.

Ce filament Ultrafuse 316L est un filament révolutionnaire, il permet via l’utilisation d’imprimante 3D FDM traditionnel la production de pièces à fritter. Le frittage est un procédé de cuisson à haute température qui permet de séparer la structure plastique du métal. Ce frittage fait alors entrer le métal en fusion permettant une liaison efficace et homogène.

Ce processus d’impression en 2 étapes débute chez vous via l’impression de la pièce à fritter (dite verte) puis via l’intervention d’un prestataire pour l’étape de frittage. Cette combinaison de filament ultra technique et d’un prestataire externe dédié permet de minimiser les coûts de fabrication de vos pièces métalliques sans avoir d’investissement important à réaliser.

Ultrafuse 316L : les principaux points forts

Impression de métal abordable : Ce filament 316L (du nom de l’acier inoxydable le composant) développé par BASF est le premier filament permettant l’impression d’une pièce en métal à fritter. Accessible pour la majorité des imprimantes 3D du marché, ce processus d’impression en 2 étapes est rapide, efficace et peu coûteux.

Bonne imprimabilité : La conception de ce filament hautement composite est développée autour d’une matrice plastique permettant un bon glissement du fil, une extrusion efficace et une bonne liaison inter-couche malgré ce fort taux de métal.

Méthode de frittage optimale : Ce filament Ultrafuse 316L rend l’accès à une solution de frittage spécifique à ce filament facilement accessible. Via l’acquisition de coupon dédié (1 coupon = 1 kilo de pièce à fritter), il est simple et rapide d’accéder à cette solution de post traitement.

Si vous souhaitez davantage de renseignements sur le sujet, nous vous invitons à consulter les guides disponibles en téléchargement et le système de fonctionnement du coupon dans la fiche dédiée.

Nos recommandations d'emploi avec le BASF Ultrafuse 316L

Le filament Ultrafuse 316L est un filament qui nécessite un paramétrage spécifique. Il est fortement recommandé d’utiliser les profils d’impression existants afin de respecter les contraintes propres à ce filament. L’impression doit être précise et uniforme, densité de remplissage, épaisseurs de coques, flux, ces paramètres sont extrêmement importants pour la seconde phase de traitement.

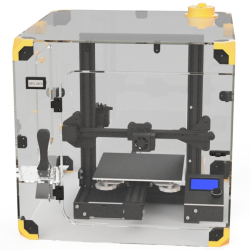

Une gestion des supports bien spécifique est également nécessaire et l’utilisation de la double extrusion aidera grandement pour cette partie. Ce filament est compatible avec la majorité des imprimantes FDM mais est réellement conseillé sur les imprimantes professionnelles.

Attention à ne pas dépasser la température d’extrusion recommandée sous peine de forte toxicité.

L’utilisation d’une colle spécifique type Magigoo Metal sera également recommandée pour limiter la déformation de vos pièces pendant l’impression.

Nous vous invitons à consulter les documents en pièces jointes afin de récupérer les données et informations essentielles pour l’impression de ce filament si particulier.

Nous serons bien évidemment disponibles pour vous accompagner et vous guider dans cette utilisation.

- 🎯 We collaborate with businesses.

- 📦 Stock in Europe

- 🚚 Ships within 24 hours

- 🔐 Secure payments

- 🔙 14 days to change your mind

- 📱 Need advices ? Contact technical support

Specifications for Ultrafuse 316L Metal BASF - 2.85mm - 3 kg

Technologie / Produit

- Technology

- FDM

- Material

- Other

- Visual aspect

- Opaque

- Diameter

- 2.85 mm

- Sensitivity to humidity

- Strong

- Odour

- Yes

- Harmful

- Yes

- Level of difficulty

- Expert

- Brand

- BASF

- Type of product

- 3D Filament

- Colour

- Natural

- Net weight

- 3 kg

Valeurs techniques

- Specific properties

- Metal to be sintered

- Resistors

- Mechanical engineering

Extrusion

- Nozzle type

- Tempered steel, Ruby

- Type of consumable

- Non-proprietary filament (open system)

- Min. plateau temperature

- 90 °C

- Max. tray temperature

- 120 °C

- Min. extrusion temperature

- 230 °C

- Max. extrusion temperature

- 250 °C

- Min. speed

- 15 mm/s

- Max. speed

- 50 mm/s

- Minimum nozzle diameter

- 0.5 mm

- Bowden compatibility

- Yes

- Warping sensitivity

- Strong

- AMS compatible

- No

Équipements spécifiques

- Closed printing enclosure

- Yes

- Filtration

- HEPA, Coal

Installation / Prérequis

- Type

- Filament on spool

- Box supplied

- Yes

- Coil material

- Plastic

- Also find this product Ultrafuse 316L Metal BASF - 2.85mm - 3 kg in these categories:

- 3D Filament

- Metal filament

- BASF

- 2.85 / 3 mm

Customer reviews about Ultrafuse 316L Metal BASF - 2.85mm - 3 kg

You might also like