- 👨🔧 Premium After-sale service

- 🚚 Free delivery from €39.90

- 📦 Return under 14 days

- ✉️ Customer service

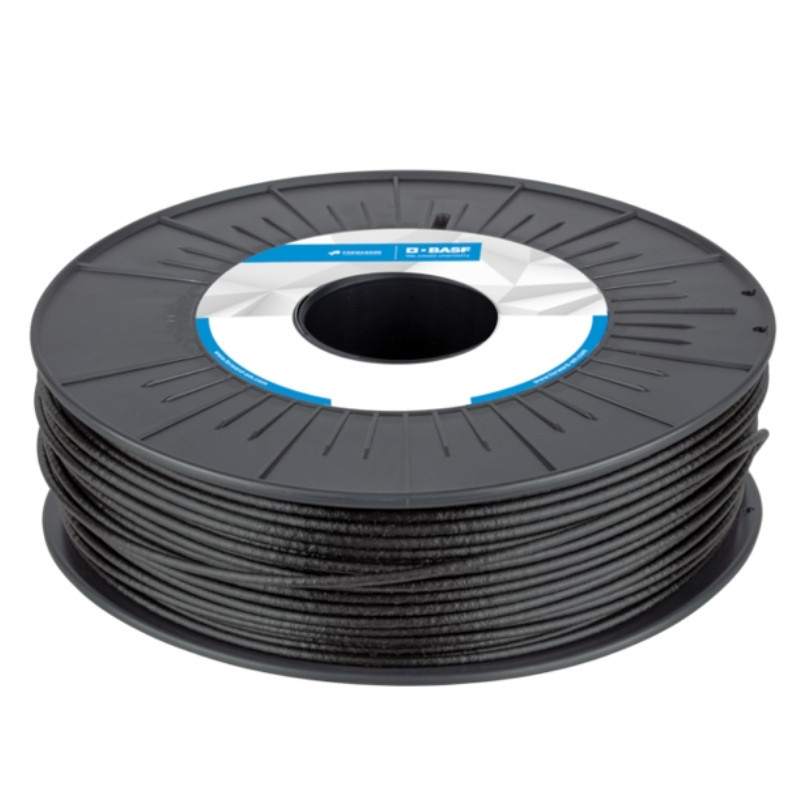

Ultrafuse PP GF30 BASF - 2.85mm - 700 g

Ultrafuse PP GF30 by BASF is a polypropylene filament composed of 30% glass fibers, specially developed for 3D printing.

This highly technical filament is used in industry for extreme applications. Ultrafuse PP GF30 provides high rigidity to your parts as well as excellent resistance to heat, UV, and chemicals.

VAT at 20%, which is €89.88 TTC including tax.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Our experts are at your service to answer your questions and provide advice at info@polyfab3d.com.

Delivery within 48/72 hours

Order before 1pm. Same day shipping

Free delivery

Free delivery near you from €69.90

Premium support

Our teams are on hand to answer all your questions

Over 2000 products

A wide choice of products from the biggest brands

Ultrafuse PP GF30 BASF – Technical Filament Reinforced with Glass Fibers

Ultrafuse PP GF30 from BASF is a technical polypropylene-based filament reinforced with 30% glass fibers, specially designed for 3D printing. Ideal for demanding industrial applications, it offers excellent mechanical performance and high stability.

Key Advantages of PP GF30 BASF:

- Very high rigidity thanks to glass fiber reinforcement

- Outstanding heat resistance for durable parts

- Excellent resistance to chemicals and UV

- Perfect for functional or outdoor parts

Recommended Applications:

This filament is particularly suited for: Automotive - Technical tooling - Components exposed to high mechanical or thermal stress

- 🎯 We collaborate with businesses.

- 📦 Stock in Europe

- 🚚 Ships within 24 hours

- 🔐 Secure payments

- 🔙 14 days to change your mind

- 📱 Need advices ? Contact technical support

Specifications for Ultrafuse PP GF30 BASF - 2.85mm - 700 g

Technologie / Produit

- Technology

- FDM

- Material

- PP

- Visual aspect

- Opaque

- Diameter

- 2.85 mm

- Sensitivity to humidity

- Low

- Application

- Prototyping, Functional part

- Odour

- Yes

- Harmful

- Yes

- Level of difficulty

- Expert

- Brand

- BASF

- Type of product

- 3D Filament

- Colour

- Black

- Net weight

- 700 g

Valeurs techniques

- Glass transition temperature

- -5 °C, -5

- Deflection temperature under load (0.45 MPa)

- 127 °C

- Deflection temperature under load (1.8 MPa)

- 73 °C

- Charpy

- 23 kJ/m² of energy

- Specific properties

- Waterproof

- Resistors

- Mechanical engineering, Chemical

- Composite

- Glass fibre

- Percentage of fibre

- 30 %

- Tensile modulus

- 2628 Mpa

- Flexural modulus

- 3507 Mpa

- Tensile yield strength

- 42 MPa

- Tensile strength

- 77 MPa

- Maximum elongation at break

- 4.4 %

- Density

- 1.06 g/cm3

Extrusion

- Nozzle type

- Tempered steel, Ruby

- Type of consumable

- Non-proprietary filament (open system)

- Min. plateau temperature

- 20 °C

- Max. tray temperature

- 40 °C

- Min. extrusion temperature

- 240 °C

- Max. extrusion temperature

- 260 °C

- Min. speed

- 30 mm/s

- Max. speed

- 80 mm/s

- Minimum nozzle diameter

- 0.5 mm

- Bowden compatibility

- Yes

- Warping sensitivity

- Strong

- AMS compatible

- No

Équipements spécifiques

- Closed printing enclosure

- Yes

- Filtration

- HEPA, Coal

Installation / Prérequis

- Type

- Filament on spool

- Box supplied

- Yes

- Coil material

- Plastic

- Also find this product Ultrafuse PP GF30 BASF - 2.85mm - 700 g in these categories:

- 3D Filament

- Polypropylene (PP)

- Glass fiber filament

- BASF

- 2.85 / 3 mm

Customer reviews about Ultrafuse PP GF30 BASF - 2.85mm - 700 g

You might also like