- 👨🔧 Premium After-sale service

- 🚚 Free delivery from €39.90

- 📦 Return under 14 days

- ✉️ Customer service

- 🎯 Services dedicated to professionals

- 📦 Stock in Europe

- 🚚 Ships within 24 hours

- 🔐 Secure payments

- 🔙 14-day return

Food contact

Active filters

Food contact

Filaments with the American FDA or European CE food standard authorise them to come into contact with food. Certain materials such as PETG or PP are intrinsically food-safe. Some filament manufacturers have therefore perpetuated this characteristic by manufacturing in compliance with this standard.

As with all food-related applications, the standards apply to the raw filament on the spool. The transformation process generated by 3D printing automatically triggers a transfer of this responsibility.

Users of 3D-printed parts that come into contact with food must take responsibility for complying with the usual practices relating to this environment. As long as your entire process complies with the good practices already in place in the food industry, there is no risk of contamination or pollution.

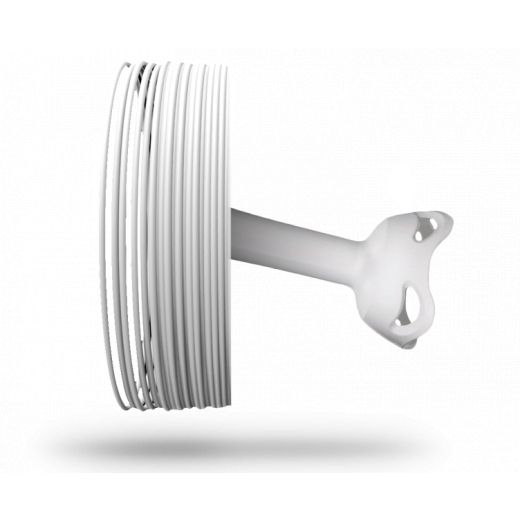

From a practical point of view, the use of food-compatible filament (FDA) must be accompanied by a dedicated 3D printer. In fact, using different materials in the same equipment will open the door to pollution of your production, even though it is basically compatible with food contact. So it's vital to ensure that your entire extrusion system is in good condition, from the drive mechanism and its passage through the sheaths (bowden tubes) to its extrusion through the nozzle. In this context, we recommend the use of steel nozzles rather than traditional brass.

3D filaments compatible with food contact are often technical materials with high mechanical performance. PETG is rigid but robust, whereas PP is semi-rigid, foldable and tear-resistant. These filaments are frequently found PP in the form of bottles and packaging, because they enable even thin objects to retain their watertightness and impact resistance properties.

How do you choose a food-compatible filament?

Despite the intrinsic food properties of certain types of 3D filament, it is important to check the technical or safety data sheets for the presence of FDA and/or CE approval for food contact. Some manufacturers guarantee that this food compatibility will be extended, because they are committed to respecting these good practices. As a reminder, from a technical point of view, the manufacture of filament for 3D printing is already a transformation of the original raw material. It's the same process that applies to you as a new converter of this raw material that has already been shaped once.

Which food contact (FDA) filament should I choose?

For these applications, we recommend that you concentrate on filaments made in Europe that have ideally also passed the CE standard and not just the American version (FDA). Otherwise, the colours and diameters available can also influence your choice.