- 👨🔧 Premium After-sale service

- 🚚 Free delivery from €39.90

- 📦 Return under 14 days

- ✉️ Customer service

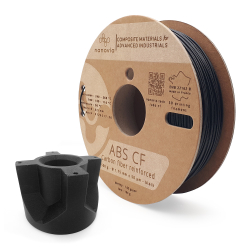

ABS Composites

Active filters

- Made In France

ABS Composites

The composite versions of ABS filaments are excellent products. They perfectly combine the performance ofABS with greater ease of use. On this point alone, ABS composite filaments are excellent choices. With less warping, improved dimensional accuracy and optimised interlayer bonding, the carbon or Kevlar fibres added to this ABS matrix offer a host of advantages, not to mention enhanced mechanical performance. Stiffness and thermal resistance for the ABS carbon version, and high isotropy and superior bending strength for the aramid (Kevlar) version.

These technical 3D printing filaments are a national speciality, and Breton manufacturer Nanoiva has been developing exceptional quality composite filaments for several years now. Our selection includes these two types of filament ABS Carbon and Kevlar.

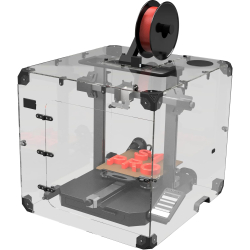

Available in 1.75 mm and 2.85 mm, these spools of filament will be abrasive for your 3D printer, so it's best to use a reinforced nozzle and ideally one with a minimum diameter of 1.75 mm 0.5mm.

The material ABS will always appreciate the addition of a cap and a high-performance adhesion glue to make the results even more reliable and to finally be able to control the ABS filament without volume constraints.

Composite versions, a closed enclosure and the right adhesive are the keys to success for your technical 3d printing projects at ABS.

Why choose a ABS composite?

Using the material ABS in 3d printing comes with a number of technical limitations. The main cause is the shrinkage of the thermoplastic generated during the manufacture of your part.

To greatly reduce or even eliminate these harmful phenomena, integrating fibre will, in a way, armour and stabilise the material. Very effective on this point, fibres (and Kevlar in particular) also play a role on the thermal side, useful during manufacture to improve the mechanical separation between the layers.

Carbon or Kevlar?

Carbon for maximum rigidity and lightness, Kevlar for resistance to bending and impact.