- 👨🔧 Premium After-sale service

- 🚚 Free delivery from €39.90

- 📦 Return under 14 days

- ✉️ Customer service

Filament ABS

Active filters

Filament ABS

The filament ABS or Acrylonitrile Butadiene Styrene is a widespread and historic material in 3D printing. This amorphous thermoplastic is very efficient and is used in industry in the form of injected products.

This material is widely used in the design of everyday parts requiring good impact and scratch resistance. The most common example of the use of this material is Lego. It is also often found in the form of protective shells or casings, as well as in furniture and office equipment.

The ABS filament is a material with some interesting characteristics: good overall strength, both mechanically and in terms of heat resistance. It has an attractive matt appearance and a very clean surface due to its rapid cooling.

This rapid cooling can, on large print formats or when using slightly low printing temperatures, cause a weakening of the interlayer bond. It is therefore strongly recommended to use a bonnet or a printer with a closed enclosure in order to maximise this bond and release the full potential of this filament ABS. Similarly, during layer-by-layer manufacture, the creation of internal tension linked to the shrinkage of this amorphous filament can lead to warping.

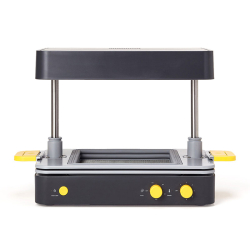

The use of a suitable adhesive or bonding solution (such as Magigoo) in addition to software artefacts such as the raft or border is also a point that should not be overlooked. A heating plate is also highly recommended.

Not to be missed when looking for maximum performance and technical sophistication from your ABS filament, the composite versions from French manufacturer Nanovia deliver some very interesting performances. These composite filaments not only improve the technical properties of the material (increased rigidity with the ABS Carbon version or impact resistance for the ABS Kevlar version) but also, and above all, their printability. No more worries about warping, shrinkage or lack of dimensional accuracy with these excellent composite versions of ABS yarns.

See here ABS filled with carbon fibre.

Why chooseABS?

The purchase of a spool of ABS filament is often linked to a need for robustness. You're looking for a part that can withstand shocks and has very good mechanical strength.

However, the ABS filament does have one major advantage, which is its price. In fact, given the mechanical characteristics of parts printed in ABS filament, its price remains one of the most attractive on the market in view of its quality.

The ABS plastic melts at a temperature of between 220° and 260°. For optimum results, an enclosure with an ambient temperature of 40° is recommended.

Which brand of wire should you choose? ABS

Polyfab3D strives to rigorously test and select the best ABS on the market. Our catalogue includes ABS from Forshape, BASF, Polymaker and Nanovia.

The leading manufacturers have also modified the formulation of their ABS to maximise its effectiveness, for exampleABS Fusion+ from BASF orABS-X from Forshape, which has the advantage of being very insensitive to warping.

As an alternative toABS, the PETG is somewhere between PLA in terms of ease of printing and ABS in terms of mechanical properties.